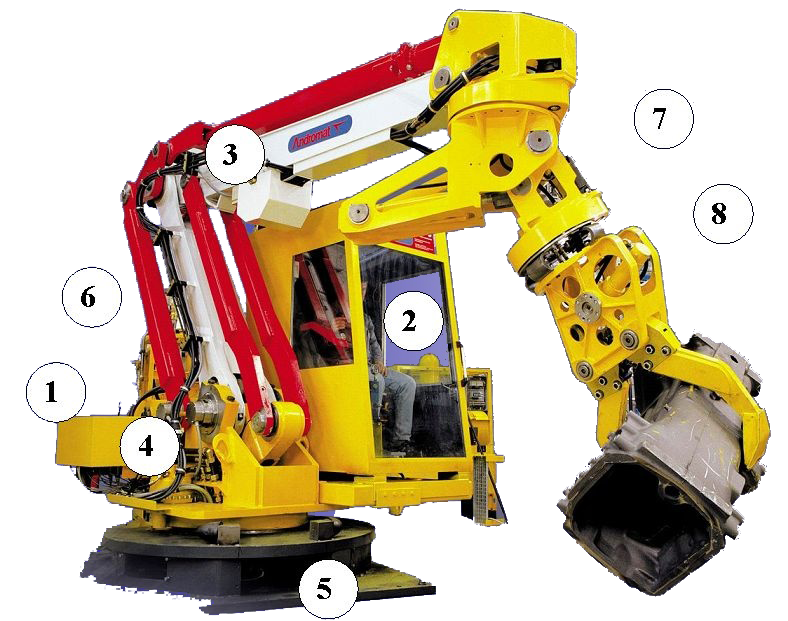

Manipulators

The concept of the ANDROMAT® AMX manipulators is based on a modular assembly structure. In this way, the optimal and most cost-effective version can be designed for every requirement. As the market leader, Henschel Andromat has a great deal of experience. Over 800 ANDROMAT® manipulators have proven themselves in foundries, forges and steelworks around the world.

This expertise in use and development is reflected in our machine concept of the new AMX manipulators.

Give us your complex task! We look forward to the challenge!

The optimization of the ANDROMAT® AMX can be found in numerous, intelligently further developed details:

-

Robust, low-maintenance spherical roller bearings, all bearing points are protected against ingress of dirt and moisture

-

All highly stressed components are subjected to an FEM analysis

-

Large axle diameter

Excellent ergonomics

In order to better protect the operator from the stresses and strains of the harsh working environment, the ANDROMAT® AMX has been noticeably improved in terms of ergonomics:

- Optional air conditioning with fresh air supply in the cabin, including filtering of the air

- Vibration dampening of the cabin through special rubber / metal elements.

- Optimal visibility through large windshield, available in heat isolation or bullet proof. Additionally, you can get sound and heat insulation for the cabin

The ANDROMAT® manipulators have “real” force feedback that gives the operator a feeling. As a result, the most difficult handling tasks can be carried out with ease.

Very Easy to Maintain

When developing the new generation of the Andromat, the focus was on ease of maintenance. Customer experiences flowed into this to a large extent.

-

Good accessibility of the control block with the hydraulic valves

-

Hydraulic lines in critical areas (heat, contact) are laid in a protected manner

-

Same drives for different movements

-

Centralized lubrication points (optional automatic lubrication possible)

-

Fixed stops of the main rotary movement (azimuth) can be individually fixed

-

Fine adjustment of the potentiometer possible without opening the housing

-

Potentiometers are plug-n-play, no soldering

-

Optimal adjustability of the valves of the positioning unit – valve connector pluggable on both sides

-

Sliding cabin for easier service

ANDROMAT® AMX 80

The strongest solution for the heavy duty range. Completely redeveloped with all the advantages of the AMX family.

ANDROMAT® AMX 70

The new AMX 70 covers the upper load range in foundries, forges and steelworks.

ANDROMAT® AMX 60

The powerful solution for the high weight range.

ANDROMAT® AMX 40

The convincing, high speed solution for the medium weight range

ANDROMAT® AMX 20/C

The compact, high speed solution for the lower weight range. The AMX 20 / C with integrated hydraulic unit.

ANDROMAT® AMX 20

The compact, high speed solution for the lower weight range.

Our manipulators offer you ergonomically designed and economical workplaces for your production and work reliably and safely under extreme environmental conditions.

Henschel Andromat Inc.

160 Commercial Court

Alabaster, AL 35007

USA

Phone: 205-664-2484 Fax: 205-664-2481 Service: 205-746-7070 Email: service@andromatusa.com